Chicken Manure Is Made into Organic Fertilizer, Environmental Protection and Profit, How Much do You Know?

For small-scale chicken farmers in rural areas, environmental pollution caused by improper management of chicken manure has become the most troublesome problem for many friends. Today, the editor specially brings you a way to deal with "chicken manure turning waste into treasure".

As the saying goes, "fat water does not flow to outsiders' fields." The "fat water" here refers to human and animal fertilizer. Nowadays, the most direct way to turn chicken manure into treasure is to use a chicken manure organic fertilizer equipment production line, using fresh chicken manure as Raw materials, after a series of processing, produce organic chicken manure fertilizer.

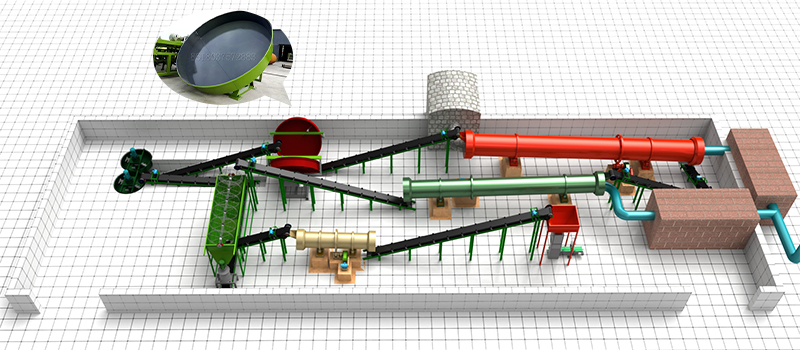

The chicken manure organic fertilizer equipment production line requires two steps to process commercial organic fertilizer: the pre-fermentation and treatment part and the deep processing and granulation part. Biological organic fertilizer equipment needs manure compost fermentation turner, organic fertilizer crusher, rotary fertilizer sieving machine, horizontal mixer disc type fertilizer pelletizer, rotary dryer, cooler, screening machine, coating machine, packaging machine, conveyor And other equipment.

Chicken manure organic fertilizer equipment production line configuration:

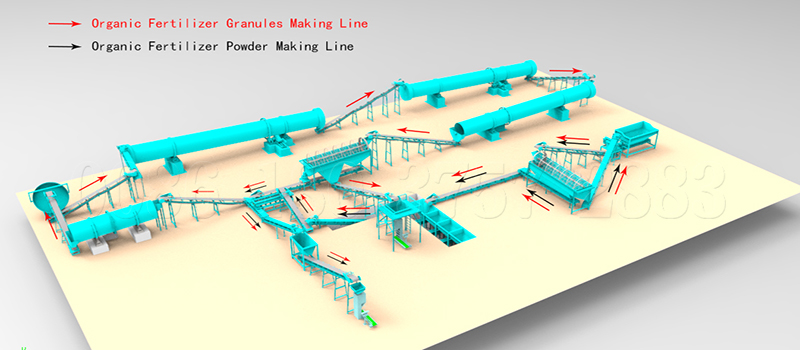

To configure a chicken manure organic fertilizer equipment production line, you can refer to the following production line configuration diagram:

Turning compost machine-forklift feeder-new vertical crusher-drum screen-dynamic batching machine-double shaft continuous mixer-mixing tooth drum two-in-one granulator-throwing circle Machine-Dryer-Cooler-Film Coating Machine-Granule Packaging Machine

Production characteristics of chicken manure organic fertilizer:

1. The chicken manure organic fertilizer equipment production line adopts a one-story layout, which reduces capital investment and is easy to operate and control.

2. The conveying equipment of the chicken manure organic fertilizer equipment production line uses belt conveyors and large inclined belt conveyors as much as possible, which not only ensures the smoothness of the conveying system, protects the particles, but also reduces the height of the plant and reduces the capital investment.

3. The granulation method chooses disc granulation, which has wide adaptability to raw materials and large output, which improves the appearance quality of the product.

Comments

Post a Comment