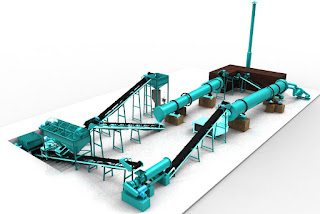

The advantages of roll extrusion granulator in the production of organic fertilizer equipment

To roll extrusion granulator by low energy consumption, high energy saving, low investment and control the emissions pollution-free characteristics such as short, equipment, set of roll extrusion pelleting machine need for debugging, debugging to take accurate method, first of all, the roller spacing between should not be too small or too large, will within the prescribed scope of mediation, secondly, lateral pressure bearing cover to avoid too loose or too tight, Will cause the shaft roll deviation, the following for you to hold a detailed introduction. First, the role of press pellet machine Roller press granulator for sale 1. Low energy consumption and energy saving roller extrusion granulation is a material granulation at room temperature. Compared with other methods, it does not need fuel, gas and other drying measures. 2. Steam granulation is a commonly used compound fertilizer production method in China without adhesive. After intermolecular condensation and crystallization, ste...