Tips About Choosing The Best Commercial Compound Fertilizer Production Line Design

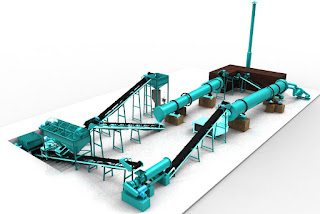

Producing fertilizer is undoubtedly an intricate process that will demand a production line adequate to suit your needs. These will be different sizes, with some other capacities, for producing fertilizer of varying capabilities. Commercial compound fertilizer production lines are one of the most prominent. They enables you to fertilize your very own crops, along with provide additional fertilizer pellets for other businesses. In order to pick one, you need to consider all of the different components that can make them up. Finally, you have to obtain one from the reliable source that offers them for inexpensive price points. These are tips which can be used to get the best commercial compound fertilizer production line in the marketplace. What Are These Capable Of Doing? As being the name would indicate, they produce compound fertilizer. This really is a fertilizer that may consist of 2 or more separate components. You are able to produce NPK fertilizer which is often used worldw...