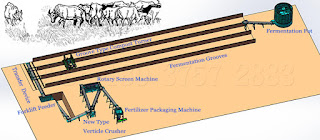

Introduction of All Supporting Systems of Organic Fertilizer Production Line

The organic fertilizer production line is a complete set of equipment with its own complete production process, which can produce organic fertilizer with high quality and high efficiency. This is also the key factor for the mass production of organic fertilizer, so let ’ s introduce the organic fertilizer production line. The configuration system allows everyone to understand the organic fertilizer production line from more aspects. 1. Granulation forming system The function of this system is to make granules from the materials after the crushed ingredients are mixed. A flat die granulator machine is suitable for granulation . Its advantages are: wide adaptability of raw materials, especially suitable for organic materials, wide requirements for raw material density and raw material moisture, and raw materials do not need to be dried. The diameter of the pressure roller is large, the template can be used on both sides, the materials are evenly distributed in ...