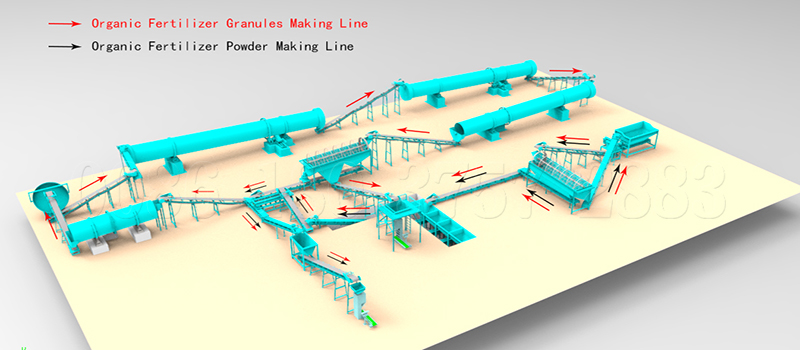

Introduction of All Supporting Systems of Organic Fertilizer Production Line

The organic fertilizer production line is a complete set of equipment with its own complete production process, which can produce organic fertilizer with high quality and high efficiency. This is also the key factor for the mass production of organic fertilizer, so let’s introduce the organic fertilizer production line. The configuration system allows everyone to understand the organic fertilizer production line from more aspects.

1. Granulation forming system

The function of this system is to make granules from the materials after the crushed ingredients are mixed. A flat die granulator machine is suitable for granulation. Its advantages are: wide adaptability of raw materials, especially suitable for organic materials, wide requirements for raw material density and raw material moisture, and raw materials do not need to be dried. The diameter of the pressure roller is large, the template can be used on both sides, the materials are evenly distributed in the compression chamber, the granulation is stable, the granulation rate is high, and the finished granules have a uniform appearance and are not easy to be broken. No water is added during the whole pelletizing process, saving the cost of subsequent pellet drying. The raw material crushing fineness is not high, and the granulating raw materials (after composting) generally do not need to be finely crushed. The fine stones can be crushed directly, and it is not easy to block the die hole of the press plate.

2. Ingredients, crushing and mixing system

The function of this system is to crush, mix and mix the composted materials, NPK inorganic fertilizers and other additives in a certain proportion. Based on many years of experience, the equipment recommendations are as follows: the use of a vertical crusher to crush cattle dung compost is not easy to stick to the wall and not easy to block, and the multi-layer turbulent chain hammer structure improves the crushing performance. The continuous automatic batching system is suitable for the dynamic measurement and batching control of organic fertilizer equipment raw materials. The mixing operation is equipped with a double-shaft continuous mixer, which has good sealing performance, and the sticky and wet materials are not easy to adhere to the root of the mixing shaft.

3. Screening and material return system

The granules output from the granulation forming system have certain differences in particle size and need to be sieved and classified. The selected rotary fertilizer screening machine requires low vibration, low noise, convenient screen change, and is equipped with a screen surface cleaning device. It is recommended to be equipped with an automatic material return system to screen out unqualified large and small particles, convey them through a belt elevator, and send them to the granulator to continue granulation after re-pulverization, which helps to improve the continuous operation capacity of the organic fertilizer production line.

4. Particle drying system

The function of this system is to further remove moisture from the sieved particles to meet the standard requirement of organic fertilizer moisture content. The granule drying generally adopts a high-efficiency three-cylinder dryer to improve the granulation shape while drying.

5. Particle cooling system

The function of this system is to realize the cooling of the granular materials after drying, which is helpful for the storage and quality of the granules. The hot particulate material output from the dryer enters the countercurrent cooler from above, and the dry air enters from the lower part of the cooler under the action of the cooling fan, and exchanges full cold and heat with the wet and hot particles from the upper end. After cooling, the difference between the particle temperature and the ambient temperature is less than 5℃. It has a swing-type turning plate unloading mechanism controlled by a pneumatic system, the unloading speed is adjustable, and the unloading is uniform and smooth. Compared with the drum cooler to cool organic fertilizer, the advantages of the countercurrent cooler are: less space, low price, and good cooling effect.

6. Finished product packaging system

The cooled granular materials are transported into the finished product warehouse through the bucket elevator. Granular materials can be quantitatively weighed and packaged through an automatic fertilizer packing scale. The automatic packing scale adopts microcomputer control, which can realize multi-range measurement. It has the functions of high weighing accuracy, automatic bagging, sewing, automatic tare weight and detection. Its advantages are unmatched by manual packing.

7. Control system

The entire organic fertilizer making line has many equipment. In order to ensure the normal and orderly production of continuous production, the control system is recommended to adopt a centralized display, centralized control and on-site control in the central control room. A control cabinet and an analog screen are installed in the control room. Console and computer system. Through the simulation screen, the equipment can be started and stopped. For equipment such as the granulator that is far away, it is equipped with an on-site control cabinet, which is convenient for on-site operation. The batching and mixing system is controlled in real time by the computer according to the formula, which can dynamically monitor the operation status of the equipment. It has the functions of formula and batch setting, modification, and storage. It has the functions of generating and printing shift, daily and monthly reports for various materials and total output. Convenient production management.

The above is the introduction of the configuration system of the organic fertilizer making line. It is precisely because of these systems that a complete organic fertilizer production line is formed. All of the above are indispensable. I will introduce these to you. I also hope that someone who wants to invest in the establishment of an organic fertilizer production line Yes, you can learn more about it.

Comments

Post a Comment