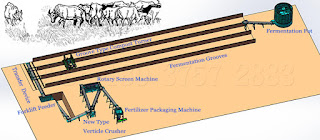

Drum Screening Machine for Compound Fertilizer Production Equipment

Drum screening machine is a commonly used equipment in the production of compound fertilizer . It is mainly used to separate the finished product and the returned material, and can also realize the classification of the finished product, so that the finished product can be evenly classified. The combined screen is convenient for maintenance and replacement. The machine has simple structure, convenient operation and stable operation. The rotary drum sieving equipment is composed of a motor, a reducer, a drum device, a frame, a sealing cover, and an inlet and an outlet. The roller device is installed on the frame obliquely. The motor is connected with the roller device through a reducer through a coupling, and drives the roller device to rotate around its axis Features of drum screening machine l The screening efficiency is high. Because the equipment is equipped with a plate-type screen cleaning mechanism, during the screening process , no matter how viscous, wet, or miscellaneou