What Issues Need to Be Considered When Investing in An Organic Fertilizer Plant?

Investing in the construction of an organic fertilizer plant is not a simple matter, nor can it blindly invest based on what others have done well. It is necessary to consider in advance the problems encountered when building a plant. Today, FPC organic fertilizer equipment supplier summarized the following points for everyone, and I hope it will be helpful to the bosses who want to build a factory!

The source of raw materials

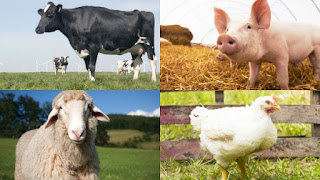

The source of raw materials is the basic issue in the production of organic fertilizer, and it is also an important indicator of profitability. Abundant sources of raw materials and low prices are the most basic guarantee for an organic fertilizer processing factory. The principle of proximity should also be followed to facilitate the purchase and transportation of raw materials. Raw materials can generally be selected from livestock manure (chicken manure, pig manure, sheep manure, cow manure, duck manure), rabbit manure, earthworm manure, fish manure, domestic waste, food waste, straw falling leaves, soybean meal and okara, etc. Such resources or channels are recommended bosses can consider building a factory.

Production process

The production process of organic fertilizer directly affects the investment plan of the organic fertilizer processing plant and the configuration plan of the organic fertilizer equipment. The conventional production process is divided into a powdery organic fertilizer production line and a granular organic fertilizer production line. The determination of which production process should be based on the results of market surveys, especially the local demand for organic fertilizer products. If it is impossible to determine, the powdered organic fertilizer production plan can also be implemented first, and then upgraded according to market needs in the later period. Never blindly implement the production process of glume grains.

Another point is the production formula of organic fertilizer. A good formula can not only meet the standard requirements, but also can be produced at the lowest cost.

Factory construction and equipment investment

After the predetermined plan is formulated, the implementation stage is reached, so at this time, we must find an experienced organic fertilizer equipment factory for analysis and guidance. Because many situations in the actual construction investment will exceed the expected plan, if the feasibility check is not carried out, then most people will fall in the middle of the road, resulting in a shortage of funds and a situation where it is difficult to get off the ground.

Equipment investment includes production equipment. As the name suggests, production equipment is mechanical equipment for the production of organic fertilizers, which generally include fertilizer pelleting equipment, crushing equipment, dumping equipment, blending equipment, fermentation machines, auxiliary equipment, etc.

The construction of the factory should follow the following principles:

l The construction of the factory area should follow the principle of proximity, close to the raw material producing area, sufficient supply of raw materials, and low prices.

l The plant area should choose a remote area with convenient transportation to ensure the normal supply of water and electricity.

l The plant construction and layout plan should be planned reasonably and conform to the correct process of organic fertilizer production. Related successful cases can be used for reference, and the feasibility judgment of experienced enterprises can be consulted.

l Comprehensive calculation of plant construction investment and pre-profitability, and reasonable planning of plant investment scale.

Comments

Post a Comment