How Much Is a Set of Organic Fertilizer Equipment? How Should It Be Used?

How much is a set of organic fertilizer equipment? How to use it, here is an explanation. A set of organic fertilizer equipment is not what we imagine or is a fixed equipment, but it needs to be determined according to the site and materials. Just like chicken manure has a lot of water, the water must be reduced during fermentation. You can add corn cobs broken up with straw, otherwise it will not be made into pellets. The sheep dung is relatively dry, and it can be pelletized directly without adding straw or the like when the moisture is controlled when the enzyme is generated. The equipment used in different processes is also different.

Small-scale organic fertilizer equipment is about 35,000 to 90,000 US dollars, and each organic fertilizer production line is different. The low configuration of the chicken manure and pig manure organic fertilizer production line only requires a grinder, agitator, a granulator (optional), a screening machine and a packaging machine. Therefore, the price of the entire organic fertilizer production line ranges from 30,000 to hundreds of thousands of dollars.

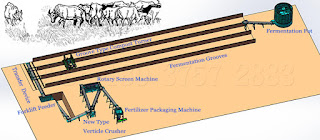

Production process: Fermentation tank puts the fermented substance - evenly sprinkle the bacteria agent - turn over the fermentation - ferment for 7-15 days -- out of the tank-sieving - crushing - pre-mixing - packaging (can increase granulation) --sell.

l The trough type compost turning equipment adopts passionate fermentation. According to the production scale, several fermentation tanks with a width of 3 meters and a length of 50 meters need to be built, and the fermented material is continuously poured into the fermentation tank. The displacement of three meters can achieve the purpose of water regulation and uniform mixing, which can save a lot of land and a lot of labor. It can achieve the purpose of being fully decomposed.

l A forklift uses a shovel to move the high-grade fermented organic fertilizer that has been turned into the fermentation tank to the semi-finished product stacking area, which is convenient for handling the high-grade fermented organic fertilizer that is thrown by the dumper every day and is discharged out of the tank in time.

l The sieving machine sifts the fermented organic fertilizer, and detects the large pieces and debris inside, which is convenient for the next step of crushing and packaging.

l The pulverizer separates the large debris and stones in the sieved organic fertilizer and smashes them, so that it is beautiful and can ensure the quality of the product.

Comments

Post a Comment