Chicken Manure Organic Fertilizer Processing Equipment Production Line

Chicken manure compost fermentation process and advantages

If chicken manure is to be processed into organic fertilizer, it must be fermented or dried in the early stage. The chicken manure is fermented to become organic fertilizer. It is not only effective, convenient to use, but also resistant to disease, growth, and fertility. advantage.

The specific process of chicken manure fermentation:

The existing chicken manure is mixed with straw, dry soil powder or other materials in an appropriate ratio, and a starter is added to mix for semi-fermentation.

The moisture of the fermented material is kept between 60%-65%. Too high or too low is not conducive to fermentation. Too little water makes fermentation slow. Too much water will cause poor ventilation, slow heating, and produce odor. Judgment method for water content: hold a handful of material tightly, see the watermark between the fingers but not drip, and it will disperse when it hits the ground.

The fermentation time is generally 5-7 days. During the fermentation process, a chicken manure turning compost machine is used to turn the materials to make them fully contact with the air and mix with the starter evenly to speed up the progress of the fermentation and ensure the quality of the finished product. The fermented product is fluffy and dark brown, rich in nutrients, and is used in the nutrient soil for melons, fruits, vegetables, cash crops, nursery stocks and flowers, and its value is increased several times.

Fermentation procedures and technological processes

Fermentation program

1. Pretreatment of raw materials: including sorting, crushing, water content and carbon-nitrogen ratio adjustment.

2. Raw material fermentation: The cycle usually takes 15-20 days.

1) Stage: refers to the two stages of microbial metabolism in the middle temperature and high temperature in aerobic fermentation. It refers to the whole process from the initial stage of fermentation, through medium temperature and high temperature, and then the temperature starts to drop. It usually takes 10-12 days.

2) Stage: After the material undergoes stage fermentation, there is still a part of easily decomposable and a large amount of difficult to decompose organic matter, which needs to continue to be fermented to make it mature. At this time, the temperature continues to drop. When the temperature stabilizes at about 35-40℃, it will reach maturity, which usually takes 5-10 days.

3. Post-treatment: Post-treatment includes removal of impurities and necessary crushing treatment.

Process flow

1. Composting technology

Tamp the ground before the pile, and then mix and compost fermented raw materials such as manure, peat and quick decay agent in proportion.

2. Stirring, turning and stacking fermentation process

The materials are stacked in stacks, which can be arranged into multiple parallel stacks. The cross-sectional shape of the stacks is usually triangular or trapezoidal, with a height of 1.5-2.0m and a width of 4-6m. The moisture content of the piled material after mixing is 55-65.

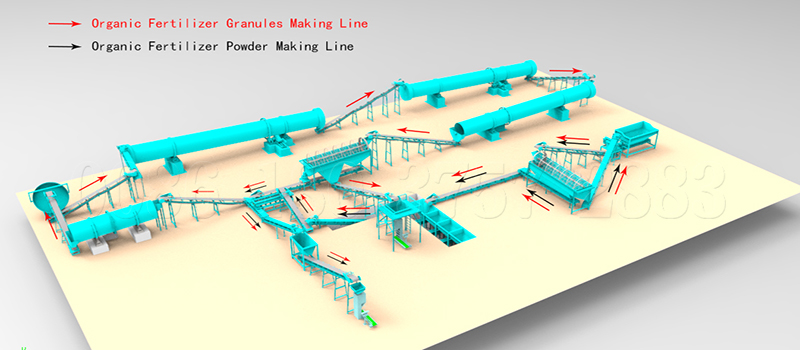

Fermentation equipment—semi-wet material crusher—mixer—granulator—dryer—cooler—coating machine—screening machine—automatic packaging machine

Comments

Post a Comment