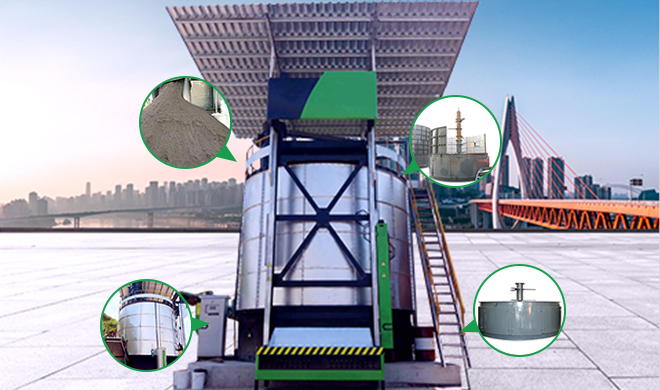

Organic Biogas Residue Fermentation Tank

The organic biogas residue fermentation tank is ventilated, oxygenated, agitated and deodorized, purified and sprayed, and the temperature of the fermentation material is controlled between 55-75 degrees. The biogas residue raw material after high temperature aerobic fermentation can be used in feed industry and animal husbandry. Auxiliary raw materials for industry, environmental protection industry, ecological agriculture, organic fertilizer industry. Biogas residue is rich in nutrients such as nitrogen, phosphorus, potassium and mineral salts, and is suitable for the development and growth of crops and livestock.

Process flow of biogas residue fermentation tank

The organic biogas residue fermentation pot uses biogas residue and other organic wastes as fermentation raw materials. The crushed materials enter the fermentation tank for heating and inoculation. At the same time, aeration is provided, and organic fertilizer fermentation agent is added to assist fermentation. The biodegradable biogas residue materials are fermented. After completion, it is screened to separate the impurities, and finally passes through the solid-liquid separation equipment to form two kinds of solid and liquid fertilizers.

Selection and price of organic biogas residue fermentation tank

The price of biogas residue fermentation tanks varies according to different models and types of fermentation tanks. The normal types of fermentation tanks include vertical fermentation tanks and horizontal fermentation tanks, and each type of fermentation tank has There are different models.

According to the fermentation tank processing capacity, the commonly used models are 3 cubic meters, 5 cubic meters, 10 cubic meters, 20 cubic meters, 30 cubic meters, 40 cubic meters, and 50 cubic meters.

The materials of various models are divided into carbon steel, stainless steel, heating method, and heat conduction method, and the price is very different.

Therefore, when choosing a biogas residue fermentation tank, one should not consider the price in a broad sense, but also depends on the material, production technology, manufacturing technology, and advanced level of operation technology.

Functional characteristics of organic biogas residue fermentation tank

1. The tank body is closed: the tank body adopts a fully enclosed type, and the waste gas produced by fermentation is processed by the waste gas treatment system, and then discharged from the tank to eliminate secondary pollution.

2. Heat insulation treatment: The interior of the tank is made of polyurethane as an insulation layer, which is less affected by the outside world and ensures fermentation throughout the year.

3. Drive design: hydraulic drive, large thrust, can ensure full load operation of the decomposed substance in the tank, ensure safe and reliable operation, and low maintenance cost.

4. Long life: 304 stainless steel is used for all parts in contact with feces, which is anti-corrosion and has a long life.

5. Electrical control: It adopts PLC chip automatic and manual control system, which is convenient for operation and control.

6. Save land: This equipment adopts three-dimensional design to save the use area of land.

Application of biogas residue fermentation tank

The biogas residue fermentation tank combined with biogas residue contains relatively balanced nutrients and rich organic matter. It is a high-quality fertilizer with slow speed and soil-improving effects. According to experiments, the content of organic matter, nitrogen and phosphorus in the soil using biogas residues is higher than that in the soil without biogas residues, while the density of the soil decreases, the porosity increases, and the physical and chemical properties of the soil are improved.

Comments

Post a Comment